Stencil Technology for SMT production

Stencils are used by electronic manufacturers today to print solder paste, which forms deposits on a printed circuit board (PCB) to hold the electronic components in place. When reflowed, the components are then secured to the PCB.

In comparison, solder paste printing is similar to painting a wall in your home yet with one important difference. In order to precisely deposit solder paste, it must be applied to a specific position and its volume must be controlled.To accomplished this precision task, it is necessary to use a special steel plate called a stencil to control the printing of solder paste.

A stencil is a pre-made template that transfers solder paste to a bare PCB through a relative aperture layout. The stencil can be made of stainless steel foil, ploy film or other material. But stainless steel foil is the most popular stencil material because it can deliver high solder paste printing quality. Precise solder paste printing is the key step for accurate circuit board soldering; however, there are other important elements to consider to ensure quality solder paste printing:

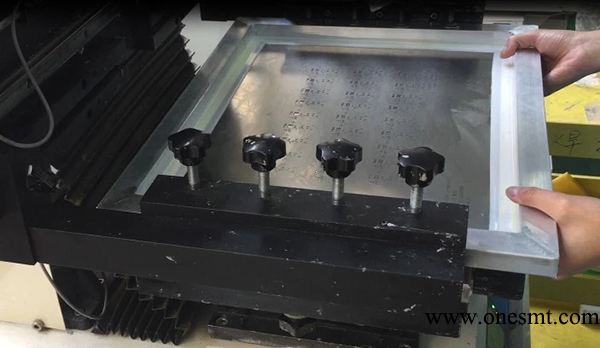

Stencil Installation

Poor stencil alignment will cause a solder bridge or an insufficient amount of solder after reflow. So, it is important to take a little extra time to ensure there is precise alignment between the PCB and the stencil.

Semi-auto LED screen printer

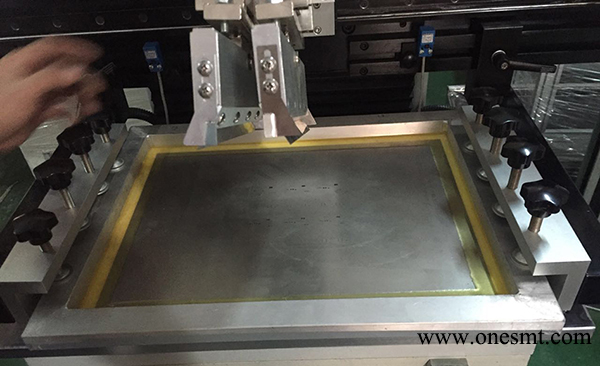

Squeegee and Blade Set Up

After the stencil is mounted firmly on the bare PCB, solder paste will be applied to the stencil. To start printing, a squeegee blade is utilized to fill in the stencil apertures with solder paste. The pressure and speed of the squeegee stroke will determine the printing quality.

Semi-auto LED screen printer

Squeegee pressure

The blade pressure will affect the volume of solder paste deposited. More pressure will cause less solder paste to be deposited because the pressure will squeeze the gap between the stencil and the PCB.

Semi-auto LED screen printer

Blade stroke speed

The speed of the blade stroke will directly affect the shape and the amount of solder paste deposited, which in turn directly affects the quality of the solder paste printing. Generally, the blade stroke speed should be set between 20 ~ 80mm / s. The speed of the blade must be adjusted relative to the viscosity of the paste. If the solder paste has greater liquidity, the blade stroke speed can be faster. Of course, the amount of solder paste used will be less if blade moves faster.

Release

Don’t release target PCB from the machine prematurely. Otherwise, it will cause the solder paste shape to deform and may affect the next assembly process.

Cleaning

Clean the stencil thoroughly to remove any solder paste and flux residues. This will prepare the stencil for the next printing.

OUBEL also can provide a semi-auto LED production line:

Semi-auto LED production line

If you are interested in this machine,pls contact vicky@obsmt.com, we will reply ASAP!