描述

Economic 6 zones lead free reflow oven

Features

1.Heating system applies to the Leadsmt Patent Heating technology .

2.Applies to the imported large current solid state relay has no contact output, and it is safe and reliable. It is equipped with a special SSR radiator, and the efficiency of heat dissipation is greatly improved, longer lifespan.

3.The heating parts are imported high quality components to ensure the high stability and reliability of the system, and ensure a longer service life.

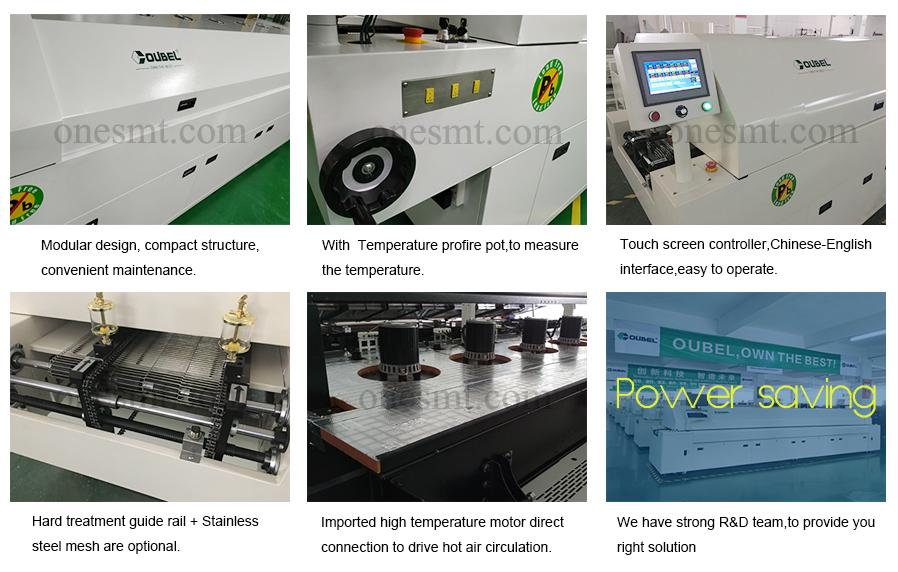

4.The modular design of the heating area is convenient for maintenance and disassembly.

5.With buzzer and light alarm when the temperature unnormal. With Touble analysis function.

6.Independent small circulation design, up and down heating mode, good thermal compensability, high thermal efficiency, electricity saving, fast heating speed, suitable for BGA and CSP and other components of high quality products welding. The special forced air circulation structure system enables the PCB and components to be heated evenly, with high efficiency and fast heating speed.

7.The winding system adopts advanced channel design, with uniform air distribution and high heat exchange efficiency.

8.Pre-heating zone, welding zone, cooling zone, cooling zone, up and down heating separately ,independent cycle and temperature control ,adjacent/beside zone temperature difference maximum value can reach 100 ℃. No temperature exchange between zones, each zone temperature and wind speed can be adjusted.

9.Applies to the imported high temperature motor direct connection to drive hot air circulation. Good balance of hot air, stable operation, longer lifespan and low noise!

10.With touch screen+ PLC controller, English-Chinese interface. Easy to operate.

11.Fast warm up.From Room temperature to working temperature need 20minutes.with hot compensation functions.

12.Modular design, compact structure, convenient maintenance.

13.Independent cooling zone ,ensure the low temperature when PCB come out .

14. Transmission system adopts Japanese Frequency Motor,combined with 1:150 imported turbine reducer, running stably, the speed at 0-1500mm/min is adjustable.

15.Standing supported by independent wheels, with special stainless steel mesh belt,durable wearing resistant, especially for BGA, CSP and 0201 welding .

16.Hard treatment guide rail + Stainless steel mesh are optional.

Specifications

| Model | OB-660 | |||||||

| Dimensions | 3600*750*1400mm | |||||||

| PCB width | 50-250mm | |||||||

| Heating zone quantity | Up 6, down 6 | |||||||

| Heating zone length | 2400mm | |||||||

| Cooling zone quantity | 0 (By cooling fan on exit part) | |||||||

| Total Power | 20KW | |||||||

| Normal working power | 5KW | |||||||

| Power supply | 3P 5W AC 380℃ | |||||||

| Warm up time | 20 minutes | |||||||

| Temperature range | Room temperature-300℃ | |||||||

| Controller | Touch screen+ PLC | |||||||

| Temperature controller | PID+SSR | |||||||

| Temperature control precision | ±1 | |||||||

| Alam introduction | Tower light: Yellow-warming: Green-normal: Red-abnormal | |||||||

| Rail direction | L-R or R-L | |||||||

| Transmission method | Mesh(rail is optional) | |||||||

| Conveyor height | 900±20mm | |||||||

| Conveyor speed | 0~1500mm/min | |||||||

| Color | PC white | |||||||

| Weight | Approx.500Kgs | |||||||

评价

目前还没有评论